Q: Can we manage the shipping schedule linked with the results of production scheduling?

A: When we create a production schedule from manufacturing orders we link the orders (shipments) with the manufacturing orders. Parts makers particularly prepare manufacturing orders from future estimates and then produce them. Determined orders (shipping instructions) are made immediately before shipping. Everything is fine when there are few fluctuations between unofficial orders and already decided orders but if there are any large fluctuations we have to check to make sure we can make correct shipping after the already decided orders are received.

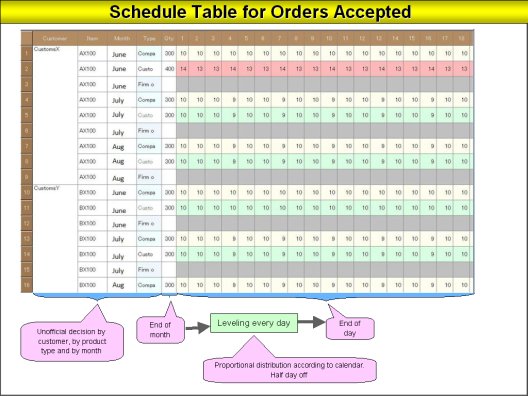

The diagram above is the Advanced Planning and Scheduling System's table of scheduled orders. The table of scheduled orders is in a format that is close to the unofficial estimate table that is in daily use by parts makers. For the flow of work:

1) Input unofficial orders.

Input monthly unofficial orders (volume shipped during one month) and automatically converts to a daily unofficial orders list based on the calendar. It can input the daily unofficial orders directly.2) From the unofficial orders the Advanced Planning and Scheduling System creates manufacture orders for manufactured products and does theory of constraints scheduling.

At this time it also performs simultaneous calculations for amount of parts and raw materials required.

Those results are then checked against unofficial data as to whether capabilities are sufficient for each process. If that capability is insufficient then such measures are taken as increasing the number of personnel. Issuing of orders is conducted at the same time and production input starts in line with the production instructions prepared before the definite orders come in.3) As shipment draws near input the confirmed orders. Daily confirmed orders replace the unofficial orders.

When orders increase the production schedule automatically changes so that shipping will be correct. If the result says that shipping cannot take place an alarm sounds. If the orders decrease there is no problem for shipping. When the orders do decrease the Advanced Planning and Scheduling System determines that there is no need to rush production and it changes the production schedule.

As shown in regard to the fluctuation of unofficial orders and determined orders the Advanced Planning and Scheduling System can see whether shipping and production are insufficient or in excess and rapidly move to prevent out-of-stock product and excess inventory.

Related articles :

Birth of the Advanced Planning and Scheduling System (APS)

Visualizing the Future Inventory of Products (Inventory Graph)

Visualizing the Future Load for Equipment and Personnel (Load Graph)