Q: Unofficial orders of parts from assemblers gives us three months' worth of parts. How can we check arrangements for purchase and the plant and equipment load?

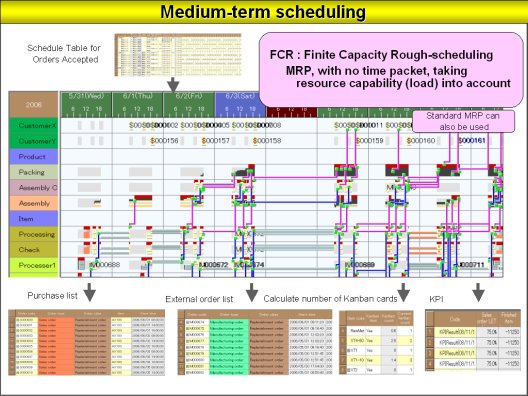

A: To make schedules mid-term scheduling automatically generates (automatically supplements) while determining lot size from unofficial orders. Mid-term and long-term scheduling uses methods of theory of constraints rough scheduling (to be described later).

The purpose of mid-term scheduling is preparation for production. The preparations for production include checks of arrangements for raw materials and process load and on the amount of just-in-time inventory.

Related purposes: Visualizing material requirements and visualizing the future load for equipment and personnel.

Related articles :

Birth of the Advanced Planning and Scheduling System (APS)

Visualizing the Future Load for Equipment and Personnel (Load Graph)

Visualizing Material Requirements

Calculating the Amount of Just-In-Time Inventory by Means of Mid-Term Scheduling