|

1. Quality control |

… |

Efficient scheduling is required, because in-progress goods have expiry dates. |

|

2. Due dates |

… |

As the production processes go farther from the material input phase, the in-progress goods become more diverged or complicated depending on their packing types,and factories do not know whether they can accept urgent orders and delivery date changes. |

|

3. Cost and Profits |

… |

Cost and profit per product should be visualized. |

|

4. Tank facilities |

… |

Efficient allocation plans, which take care of tank facilities’ complex constraints as well as cleaning maintenance, are needed. |

|

|

Asprova's high speed production schedulers |

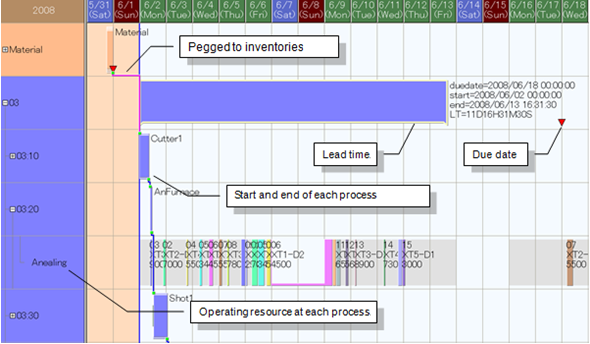

Schedulers with finite capacity make production plans which can be directly used as work instructions.

Schedulers can manage urgent orders and due date changes, allocating inventories.

♦ Order Gantt Chart: enables checking of overdue orders, wait times of each process, inventory allocation. The Order Gantt Chart’s standard feature includes a Resource Gantt Chart, an Instruction Gantt Chart, an item Gantt Chart, overdue flags. The Order Gantt Chart is easily operated with the mouse.

Asprova is capable of efficient load allocation to multiple production lines. Asprova also manages to take into account facility investment simulations and manpower employment planning. Shift changes per facility or worker are easily operated with the mouse.

♦ Load graph: current load status is recognizable in one view. Displayed periods, displayed resources, and text display are customizable at your will. In addition, inventory graphs and leading time graphs are included as a standard feature.

![]()

The “Skill map”, a table to set up process skill of employees, is provided as a standard feature. It enables managing of employees’ capacity, ability/inability and processing speed, separate to integrated master tables such as the BOM(Bill of Materials) and resource capacities.

♦ Up to 999 skill types can be added. Displays and input means are also easily customized.

![]()

Registering orders not only per production lot but also per sales order lot is possible. Production schedule planning, eliminating unnecessary inventory, can be made while taking into account safety inventories.

|

|

|

|

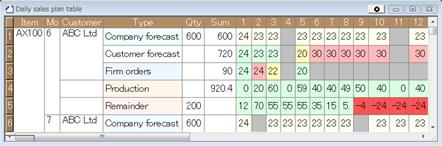

♦ Sales plan table: The information on orders for a certain period can be registered with the accuracy of company forecast, sales forecast, customer forecast, and confirmed orders. *Sales order option is required. |

♦ Inventory graph: inventory changes and material requirement can be calculated at one view. In addition, production graphs and consumption graphs are available. Calculation functionality for each term is also included. |

![]()

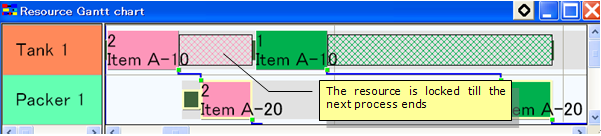

Asprova features an excellent lineup of logic options: the ”resource lock time option” which covers the constraints specific to tank facilities, the “event option” which manages cleaning event scheduling, and “time constraint MAX option” which makes consumption deadline-adjusted schedules.

♦ Resource lock time option … The constraint specific to tanks, in which materials cannot be input to tanks until the next process finishes because in-progress goods stay in the tanks.

♦ Event option: Event option generates events to occur. For example, one cleaning event is set to occur after machines are used three times in row, or one maintenance event is set to occur after machines deal with three tons of material, etc.

![]()

Key Performance Index (“KPI”) including sales, profits, profit rates, the material cost can be calculated by cost per item and working cost per resource. Calculation formulae can be freely customized. Also, standard cost breakdown can be calculated. It can be used to verify the result of facility investment simulation as well.

♦ KPI(Key Performance Index): KPI can evaluate the calculation result and keep records.

|

|

♦ KPI radar chart: KPI radar chart enables comparison of the simulation result by radar chart (with HTML View) |