Asprova Beginner's Lesson 8 -- Operation Split --

30 minutes

Learn by Movie

Download the project file of this lesson.

If you take a look to the documentation, please read the following.

What you will learn in this lesson

In this lesson, you will learn about the operation split function that splits the operation of a given process on the basis of the specified lot size and makes assignments. By splitting an operation, you will be able to schedule a production of an item in parallel using several pieces of production equipment.

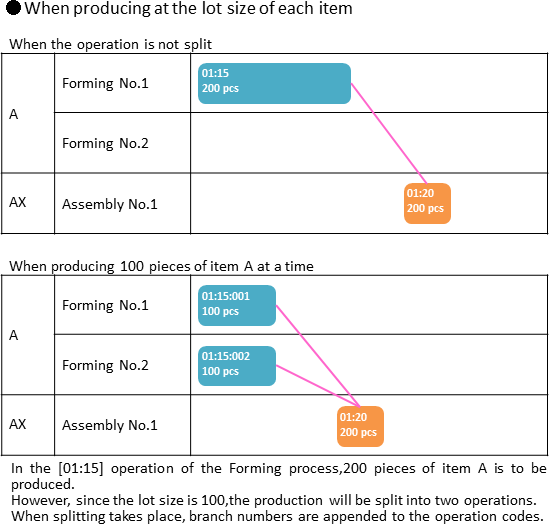

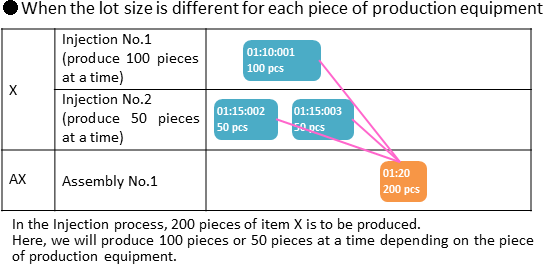

There are two ways of splitting operations in Asprova. One method is to set a lot size for each item. This method is used when the production quantity of an operation is fixed for each item. The other method is to set a lot size on each piece of production equipment. This method is used when the quantity of items that can be produced at once is different for each piece of production equipment.

The operation split function also has numerous other features such as splitting operations based on ratio and switching operators for each shift. Here we will learn the basic functionality. For more details on splitting operations, see Related Materials at the end of this lesson.

The contents of this lesson apply to MS Light module + operation split option and higher modules. The operations described here are for the MS Light module + operation split option.For information on how to switch the module and option, see "How to start Asprova" and "How to switch option for Trial".

Download the project file of this lesson.

If you have questions, please access "Q&A Center" from navigation menu of this web site.

1. Splitting an Operation by the Lot Size of Each Item

If we specify [Operation split size MAX] for an item and the production quantity of an operation exceeds the specified lot size, the operation will be split and assigned. This method is used when the lot size of production is fixed for each item.

■ Procedure

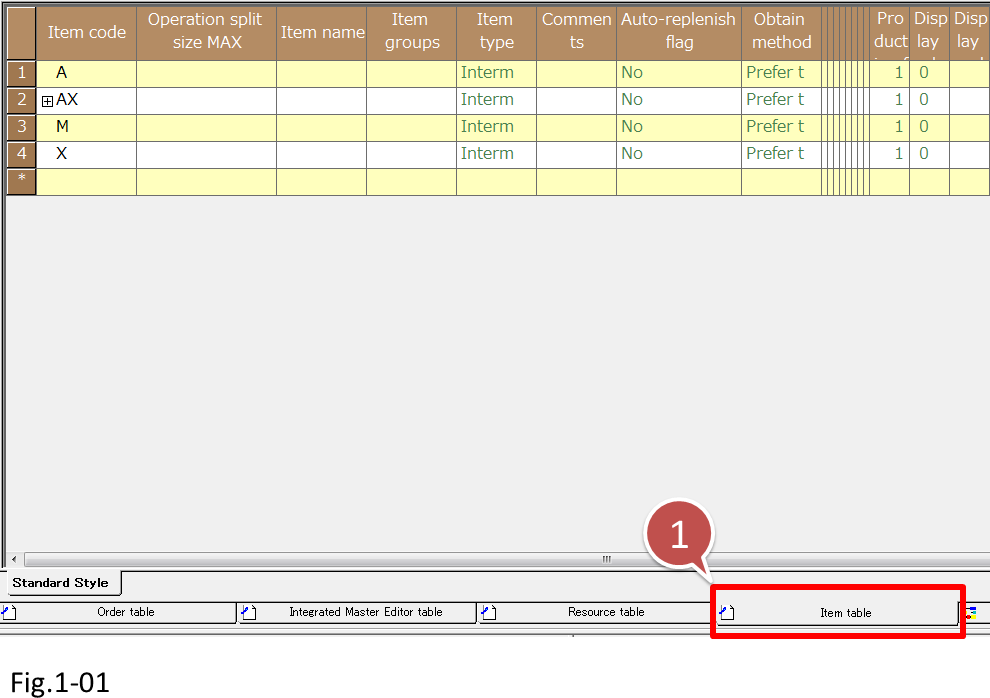

(1) Choose [Table View]-[Item] to display the Item table.

- Choose [Table View]-[Item] to display the Item table.

| Setting item | Description |

|---|---|

| Item code | Set the item code. If the item code used in the system and the item name used on-site are different, set the name to the Item name. |

| Operation split size MAX | The maximum production quantity of an operation. If the production quantity of an operation exceeds Operation split size MAX, the operation will be split in a way that Operation split size MAX is not exceeded. |

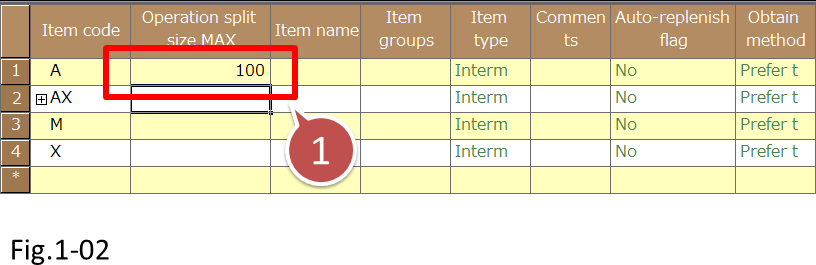

(2) Let's set [Operation split size MAX] of item A to 100. Now, whenever the production quantity of an operation that produces item A exceeds 100, the operation will be split in a way that the production quantity does not exceed 100.

- Set [Operation split size MAX] of item A to 100.

(3) Let's reschedule.

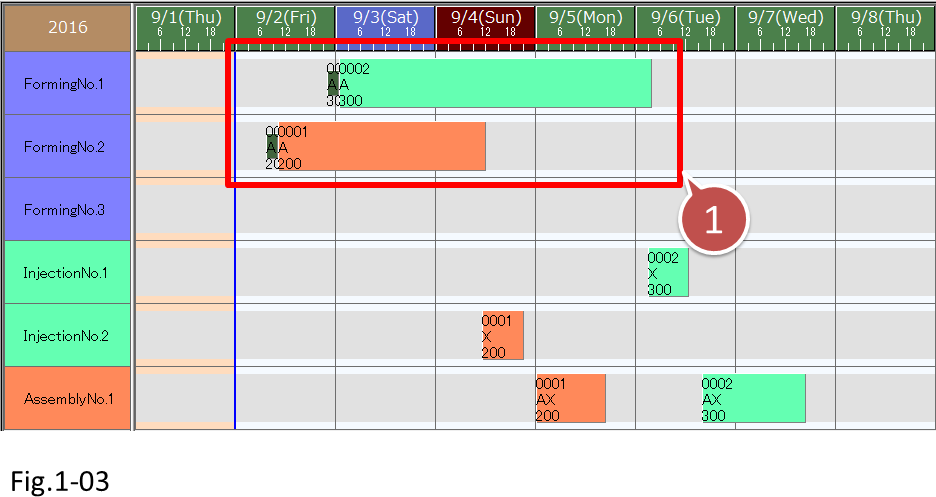

The figure below shows the rescheduling result when the Operation split size MAX is not specified and the operation is not split.

- The Operation split size MAX is not specified and the operation is not split.

When a reschedule is executed, the operation of item A will be assigned. The following process item AX is assigned so that 200 or 300 pieces are produced, but for item A, operations are split so that 100 pieces are produced at a time.

- For item A, operations are split so that 100 pieces are produced at a time.

Since the operations to produce item A are assigned 100 pieces at a time to several resources, they can be produced in parallel. We can see that the lead time is reduced.

You can view the operation information of split operations in the Operation table and Use instruction table, in the same way as the operations that are not split. Export these tables to create work instructions.

Operation splitting and time constraint method

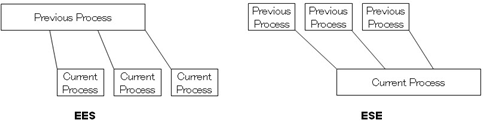

When operations are split, you can define the time constraints between operations according to the production quantity of each split operation.

You can set the Time constraint method in the Integrated Master table.

Time constraint method

| EES | When operations of the current process are split, allow the split operations to be started with respect to the specified ratios of the previous process. If the operation of the current process is not split, then the assignment will be the same as when you specified ES as the time constraint method. |

| ESE | When the operation of the previous process is split, allow the split operations to be started with respect to the specified ratios of the following process. If the operation of the previous process is not split, then the assignment will be the same as when you specified ES as the time constraint method. |

There are other time constraint methods. For details, see "Time constraint method" in the online help.

2. Splitting an Operation by the Lot Size of Each Piece of Production Equipment

Next, we will look at how to specify the lot size of each piece of production equipment to split operations. This method is used when the lot size is different for each piece of production equipment. In such a case, set the [Resource split size MAX] of resources.

Here, let's set the lot size of the Injection process resource used to produce item X.

■ Procedure

(1) Display the Resource table. Choose [Table View]-[Resource].

- Choose [Table View]-[Resource].

(2) Specify the Resource split size MAX of resources [Injection No.1] and [Injection No.2]. Set the Resource split size MAX of Injection No.1 to 100 and that of Injection No.2 to 50.

- Specify the Resource split size MAX of resources [Injection No.1] and [Injection No.2].

(3) Let's reschedule.

The operation of item X has been split and assigned according to the Resource split size MAX of each resource.

- The operation of item X has been split according to the Resource split size MAX of each resource.

Related Materials

For more details on operation splitting, see the following materials.

■ Specific issues

- (1) Splitting of operations

■ Samples

- S: Operators changeover. Splitting operations by shift time.

- For details on how to use the samples, see here.