Foreword:

Lean-manufacturing Japan is delighted to be able to publish the first part of a very fascinating interview about the various aspects of production control by leading industry expert, Tomoichi Sato.

Production Management and Planning

Introduction:

An interview with Tomoichi Sato about the importantance of planning in the manufacturing industry and how the different levels of planning interact.

Profile:

Tomoichi Sato

Senior Deputy Manager, PMP (Project Management Professional)

EPC Technology Advancement Group, No. 2 Project Division

JGC Corporation

Tomoichi Sato has been serving in system analysis and project management roles for both domestic and overseas projects. He has been involved in both the design and implementation of systems for production planning, advanced scheduling, ERP, MES and e-Procurement. He is a Registered Management Consultant for Small and Medium Enterprise (PMP). Tomoichi Sato has also authored a number of books including "Introduction to Advanced Production Scheduling", "The Art of Time Management", and "Understanding BOM/Bill of Materials" (in Japanese).

1981 MA. Graduate School of Tokyo University (Chemical Engineering).

1985-1986 Visiting Researcher at US East-West Center.

Part One:

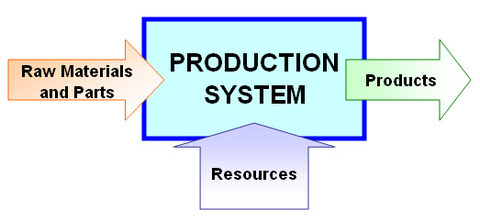

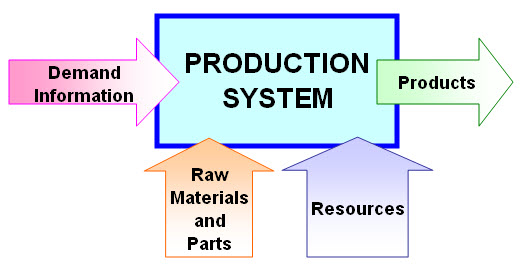

The conventional view is to regard raw materials or parts as input into the production system which converts them into the products (Figure 1).

Q. So within the overall production system, you have product management and production planning.

A. I'd say that the terminology here is a little bit confusing, or used differently. The activity to create a production plan is what I would call production control. Control is a kind of more detailed activity compared to management.

Q. Is this what we call SEISAN KANRI (production control) in Japanese?

A. One of the very confusing things in Japanese is that we only have the one term, KANRI. However, in English, we have management, control, and administration. These are different things, right? Normally management is a higher activity to oversees things, to organize people and resources, and make the system work properly. Control is more precise. Management creates the system, whilst control just operates the system. So, control is usually focused on the near future and monitors resources or people. This is a kind of feedback control, in a sense. To the contrary, management words as "feed forward". Administration is a kind of supporting work. We should be very careful when we talk about KANRI. So, I try to avoid using the word KANRI. Instead, even in Japanese, I try to use the words "manajimento" or "controru".

Q. So what is the role of the production management within the whole production system? The view is that the management is at the top giving the orders, but in fact, is their role to support the production?

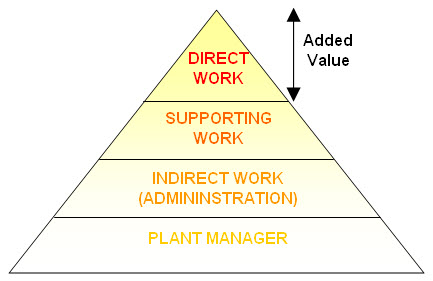

A. Let's just imagine there is a kind of craftsmanship. My father-in-law was once a craftsman. Later he became a manager within a small company, but as a starting point, he was a craftsman of wooden barrels, the smaller ones used for daily washing and the larger ones used as a bathtub etc. In the good old days, the craftsman himself received the order from the customer. Then he would pick the raw material, in this case wood, cut and assemble it. Everything is done by his own hand. And finally he delivers this product to the customer. In such a world, all of these things are done only by the craftsmen. No other activity is required. Of course, there will be some selling, invoicing and collecting things but these are done by a salesperson. In my father-in-law's case, that was done by my mother-in-law. When his business began to grow he then hired more craftsmen. As the production volume increased, what happened? There should be someone who is specialized in the purchase of raw materials and wood material, because handcrafts heavily depend on the quality of the wooden material. And also, there should be a specialized guy to store the raw materials and the finished products, take things from the warehouse and deliver products to the store. Although there are now many different kinds of specialized jobs, the core work which creates added value is still focused on the cutting and assembling. This is what we call direct work which creates added value (Figure 3).

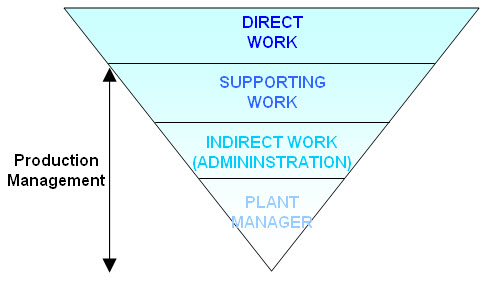

And the other work, for example, the purchasing, warehouse keeping and transportation work, these are supporting work. As the volume of work increases, the specialization of this supporting work increases the productivity of the craftsman. If there are no other people to assist then the craftsman himself has to go to the raw material supplier and negotiate, or he has to take things from the warehouse etc. In this case, his time to focus on the direct work is limited. That's why to increase the productivity of the craftsman's direct work; this kind of indirect work is shifted to the supporting people. And the more the business volume increases, then the more specialist jobs will be required, for example, someone who is specialized to deliver the raw material to each craftsman or someone who has to set up the ordering or even someone who prepares the tools needed everyday. Only the direct work creates added value. We also have the supporting work as well. However, taking raw materials from the warehouse to the shop floor doesn't create added value. So the work is necessary, but it isn't added value work. The work that is necessary, but isn't added value work, we call supporting work. We also need some specialist work as well, which is indirect work. For example, scheduling, purchasing, selling or accounting, which we can call administrative work. These people do not contribute directly to create added value, so why are these people required? These people only contribute to increase the productivity of the direct workers. In the production system, the most important people are the laborers working on direct work. The other people are helping these people so that they can work effectively and efficiently. In the larger sense, we call this kind of thing, production management (Figure 4).

Q. So the job of production management is to make sure that each person can concentrate on their job by making sure that the work environment is organized so that they don't have to worry about other things.

Tomoichi Sato

Tomoichi Sato, at the Lean Manufacturing Japan editorial office, talks about his experiences in the manufacturing industry.

Tomoichi Sato, at the Lean Manufacturing Japan editorial office, talks about his experiences in the manufacturing industry. End of Part One . . .

Please click below for Part Two of the Production Management and Planning interview.

Production Management and Planning: Tomoichi Sato (Part Two)