Classification by Production Method (part 1)

Every factory is different from others. However, it is convenient to think of them by classifying them into several patterns.

Firstly, if we want to classify them into smaller groups, we can think of industry nomenclature by the government. Japan Standard Industry Classification, categorizes the manufacturing industry into 23 middle items (please refer to the Figure in Factory Mechanism: Outline), and 164 further small items.

Similar classification will be found in each country. For example, North American Industry Classification System (NAICS) is used by USA,Canada and Mexico.

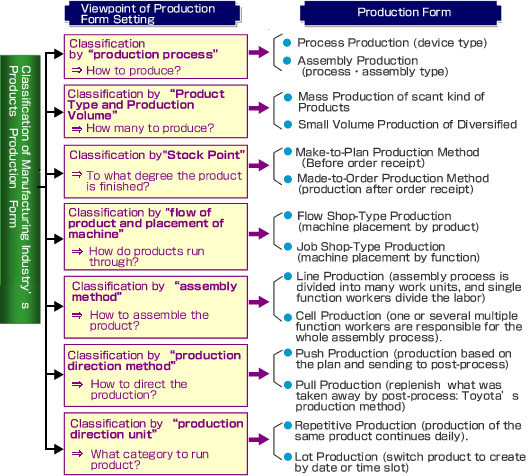

In addition, classification by dichotomy by understanding the features of the production from various points of view is very common.(please refer to the figure below.)

Firstly, the classification commonly used is whether it is the "assembly type" or "process type". This is the classification from the production process point of view, and the assembly type is the factory where parts are assembled to make a product such as an automobile factory, while a process-type factory is where the product is produced from the material through a chemical change. "Assembly type" is sometimes called "discrete type"、(and "process-type" "non-discrete") This name comes from the feature that the product is countable by units.

Another classification is from the product type point of view, which is: "mass production of scant kind of products", "small volume production of diversified products". From the standpoint of factory operation, "mass production of scant kind of products" is efficient. However, because the needs of buyers are diversified, simple "mass production of scant kind of products" is dropping away.

The classification by inventory type will be explained in the chapter as follows. "Flow Shop" and "Job Shop" are other classifications. This is the classification of how to layout the manufacturing machines in the factory. This classification is applied in the oily factory which processes metal using machines such as press machines and lathes.

"Job shop" is where devices are gathered by processing functions such as presses, lathes or welds, along with skilled technicians, each of them consists of one processing center (job shop). The manufactured goods become products by going through various job shops. The route of traveling job shops may differ product by product. Hence, scheduting and progress tracking is important in this kind of factory.

"Flow Shop" is a production site where devices are placed by order of processing of the product. When looking on the site, you can see how a product is gradually being shaped from the starting point to the ending point of the line. The flow shop is to be established when a certain production volume is estimated.

"Line production" and "cell production" are the classification used in assembly-type factory. "Line production" is where the assembly process is divided into sequential works by several workers, and workers stand in process order (stand in line) to work. I assume that our readers may have seen a photo of a factory where workers are standing alongside a belt conveyer.

As the work assigned to each worker is small and simple, the production line can be built by workers with lower wage, and the productivity during smooth operations is high. However, the line production type is difficult to respond to the fluctuation of production volume. This is because the production line is optimized to a certain production volume. In addition, since each work is simplified, it would be difficult to maintain the motivation of workers.

"Cell Production" is to create a work place (cell) by one person or a small number of workers, and manufacture products there. The necessary parts and devices are placed by cell. If the cell is made up of one person, that one person will assemble the whole parts to a finished product. Though the required skill range becomes wider, the sense of achievement will become higher. For the fluctuation of production volume, it can respond by increasing or decreasing the number of cells.

Term Comparison by Classification

"Mechanism of a Factory with Illustrations"

Published by Nippon Jitsugyo Publishing.

by Mitsuo Matsubayashi and Hiroshi Watabe.

Members of Waku Consulting Co. Ltd

Please click here for the web site of Waku Consulting.