Asprova Beginner's Lesson 11 -- Scheduling command --

30 minutes

Learn by Movie

Download the project file of this lesson.

If you take a look to the documentation, please read the following.

What you will learn in this lesson

The execution of Asprova scheduling consists of Assignment direction and other Scheduling parameters (discussed in lesson 10) and commands.

A command refers to a procedure that is executed in scheduling. With commands, you can create new scheduling parameters and specify which procedures are to be executed and the order in which they are to be executed. For example, you can manipulate rescheduling parameters so that after assigning operations, operations before and after a process that is a bottle neck can be brought closer together to reduce the lead time. In such a schedule, scheduling parameters can be combined and multiple procedures can be executed at once. This feature is called composite scheduling.

In this lesson, you will learn about the different types of commands and the scheduling command feature for making registrations. The scheduling command feature uses the scheduling parameter feature. If you have not learned about the scheduling parameter feature, go through lesson 10 first.

The contents of this lesson apply to MS Light module + Scheduling parameter + Scheduling command options and higher modules. The operations described here are for the MS Light module + Scheduling parameter + Scheduling command option.

The contents of this lesson apply to MS Light module + Scheduling parameter option and higher modules. The operations described here are for the MS Light module + Scheduling parameter option. For information on how to switch the module and option, see "How to start Asprova" and "How to switch option for Trial".

Download the project file of this lesson.

If you have questions, please access "Q&A Center" from navigation menu of this web site.

1. Scheduling Parameters and Scheduling Commands

You can register multiple scheduling parameters and switch between them using the combo box on the toolbar.

- Switch scheduling parameters using the combo box on the toolbar.

The procedures that are executed by each scheduling parameter can be specified as commands. As an example, let's see what commands make up the [Forward scheduling] parameter.

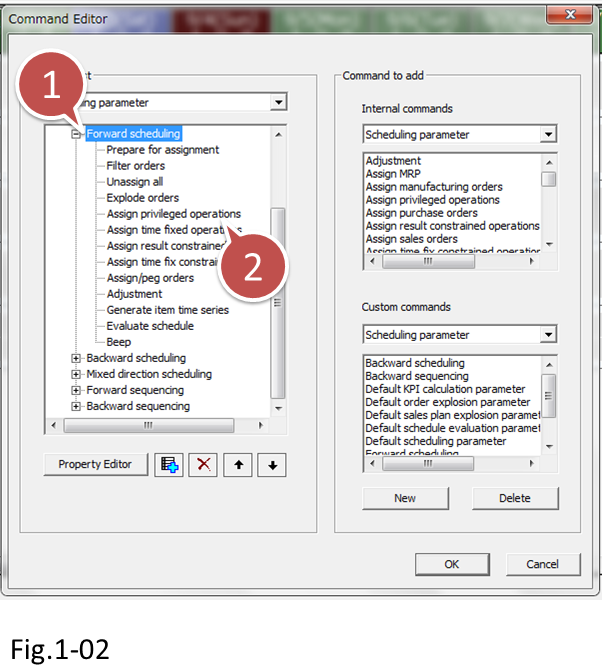

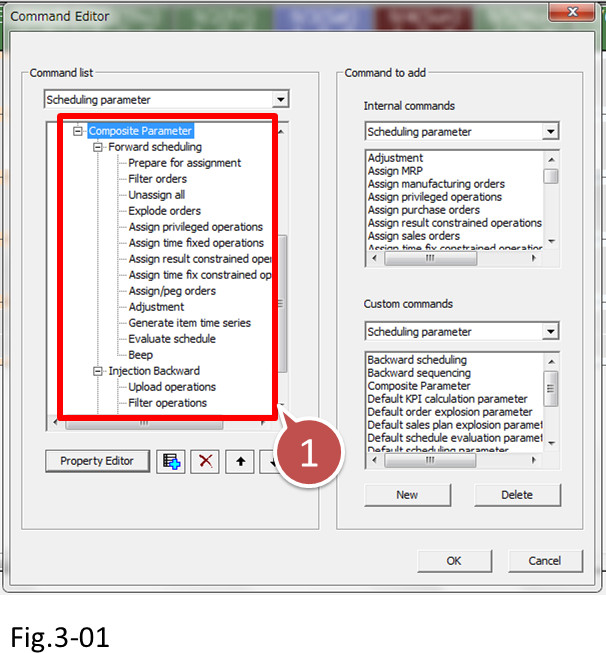

Choose [Schedule]-[Command Editor]. The Command Editor dialog box appears showing a list of Scheduling parameters and the component commands that make up each Scheduling parameter. In the following figure, the Forward scheduling command has been expanded.

- Scheduling parameters

- Commands

Numerous commands are registered in the [Forward scheduling] parameter:

- Filter operations

- Assign operations

- Evaluate schedule

The procedure that is executed by each command is different.

The following table contains representative commands and their descriptions. When you register a command, be sure to set the property values of related scheduling parameters.

| Group | Command | Description | Properties of related scheduling parameters |

|---|---|---|---|

| Object collection | Upload orders | Uploads all orders. Uploaded orders are set as an Order list in the scheduling parameter. Commands that are executed later will be applied to the orders in the Order list. | - |

| Upload operations | Uploads all operations. Uploaded operations are set in the scheduling parameter as an Operation list. Commands that are executed later will be applied to the operations in the Operation list. The operations are generated when an [Explode orders] command is executed. Be sure to execute this command first. For example, this command is used to reassign operations that have already been assigned. |

- | |

| Filtering | Filter orders | Filters orders according to the order filtering conditions set in the scheduling parameter. | Filter orders |

| Filter operations | Filters operations according to the operation filtering conditions set in the scheduling parameter. | Filter operations | |

| Unassign all | Unassign all | Unassigns all operations in the Operation list that is set in the scheduling parameter. If there is no Operation list in the scheduling parameter, all operations related to the Order list in the scheduling parameter are unassigned. If there is no Operation list or Order list, nothing is executed. |

- |

| Explode orders | Explode orders | Generates operations for each process from orders in the Order list referring process conditions set on the Integrated Master. Required quantity calculation (lesson 3), auto-replenishment (lesson 7), and inventory order assignment are also executed. Generated operations are added to the Operation list of the scheduling parameter. |

- |

| Assignment | Assign privileged operations | Assigns only the operations in the Operation list of the scheduling parameter when the status is Released, Frozen, Started, or Completed. | - |

| Assign time fixed operations | Assigns only the operations in the operations list of the scheduling parameter when the time is fixed. | - | |

| Assign result constrained operations | Use this command to prioritize the assignment of operations pegged by time constraint MAX or resource lock to other operations whose status is Released, Frozen, Started, or Completed over other operations that are not pegged. This is not necessary when the time constraint MAX or resource lock is not used. For details on time constraint MAX, see lesson 15. For details on resource lock, see lesson 16. |

- | |

| Assign time fix constrained operations | Use this command to prioritize the assignment of operations pegged by time constraint MAX or resource lock to other fixed operations over other operations that are not pegged. This is not necessary when the time constraint MAX or resource lock is not used. For details on time constraint MAX, see lesson 15. For details on resource lock, see lesson 16. |

- | |

| Assign/peg orders | Manufacturing order operations are assigned according to the dispatching rules set in the scheduling parameter. Operations for which results have been input or whose time has been fixed are not assigned at this stage. The operation is assigned and re-pegged. |

Dispatching rule Assignment direction Assignment type Resource evaluation Resource selection method |

|

| Adjustment | Checks the assignment conditions of the operations in the Operation list of the scheduling parameter and reassigns the operations that meet the conditions below. Preset scheduling parameters use the following conditions and assignments. • Backward scheduling When the assignment start time is exceeded: folded back using forward scheduling When the EST (earliest start time) is exceeded: folded back using forward scheduling • Backward sequencing When the assignment start time is exceeded: forcibly assigned When the assignment end time is exceeded: forcibly assigned When the EST (earliest start time) is exceeded: folded back using forward scheduling> |

- | |

| Time series generation | Generate item time series | Generates item time series. For details on item time series, see lesson 3. |

- |

| Evaluation | Evaluate schedule | Evaluates the schedule such as determining the number of late orders. You can use the schedule result table to view the schedule evaluation results. | - |

| Other | Beep | Generates a beep. This is mainly used to indicate the completion of rescheduling. |

- |

The following table lists the commands that are registered in the [Forward scheduling] parameter.

| Command | Properties of related scheduling parameters | Setting |

|---|---|---|

| Upload orders | - | |

| Filter orders | Filter orders | None (because all orders are applicable) |

| Unassign all | - | |

| Explode orders | - | |

| Assign privileged operations | - | |

| Assign time fixed operations | - | |

| Assign result constrained operations | - | |

| Assign time fix constrained operations | - | |

| Assign/peg orders | Assignment type | Finite capacity |

| Assignment Direction | Forward | |

| Dispatching rule | Ascending order by due date | |

| Resource evaluation | Load leveling and the like | |

| Adjustment | - | |

| Generate item time series | - | |

| Evaluate schedule | - | |

| Beep | - |

When a reschedule is executed with the [Forward scheduling] parameter, the registered commands are executed in order from top to bottom. This scheduling parameter contains all the procedures that are necessary for scheduling. For all orders, operations are generated, required quantities are calculated, operations are assigned, and schedules are evaluated.

The command construction can be changed freely. Depending on your purpose, select the appropriate commands, determine their execution order, and set the relevant scheduling parameters. The command construction is determined primarily by what you want to execute during rescheduling. Here, we will look at several scheduling command constructions and their relevant scheduling parameter properties.

(1) Scheduling parameter for reassigning only certain process operations

Like the [Forward scheduling] parameter discussed above, this is used to reassign operations that have already been assigned. In most cases, the [Upload operations] and [Filter operation] commands are used first to select the operations that you want to reassign. Then, the actual reassignment is executed. The required condition is that the [Explode orders] command has been executed, which generates the assignment target operations.

| Command | Properties of related scheduling parameters | Setting |

|---|---|---|

| Upload operations | - | |

| Filter operations | Filter operations | The operation process is equal to [Injection process]. |

| Unassign all | - | |

| Assign privileged operations | - | |

| Assign time fixed operations | - | |

| Assign/peg orders | Assignment type | Finite capacity |

| Assignment Direction | Backward | |

| Dispatching rule | ||

| Resource evaluation |

(2) Exploding orders + assignment of privileged operations and time fixed operations

This scheduling parameter is often used to perform common procedures before a scheduling parameter that filters and assigns certain operations, as in (1). Common procedures include generation of operations, required quantity calculations, and assignment of privileged operations and time fixed operations. There is no required condition.

| Command | Properties of related scheduling parameters | Setting |

|---|---|---|

| Upload orders | - | |

| Filter orders | Filter orders | None (because all orders are applicable) |

| Unassign all | - | |

| Explode orders | - | |

| Assign privileged operations | - | |

| Assign time fixed operations | - |

(3) Schedule evaluation only

A schedule evaluation is normally placed at the end of a reschedule, but this is used to execute only the schedule evaluation after moving operations or adjusting the schedule results. The required condition is that the operation on which to perform schedule evaluation has already been assigned.

| Command | Properties of related scheduling parameters | Setting |

|---|---|---|

| Upload operations | - | |

| Evaluate schedule | - |

In the next chapter, you will learn how to create new scheduling parameters and how to use the Command Editor dialog box.

2. Creating a New Scheduling Parameter

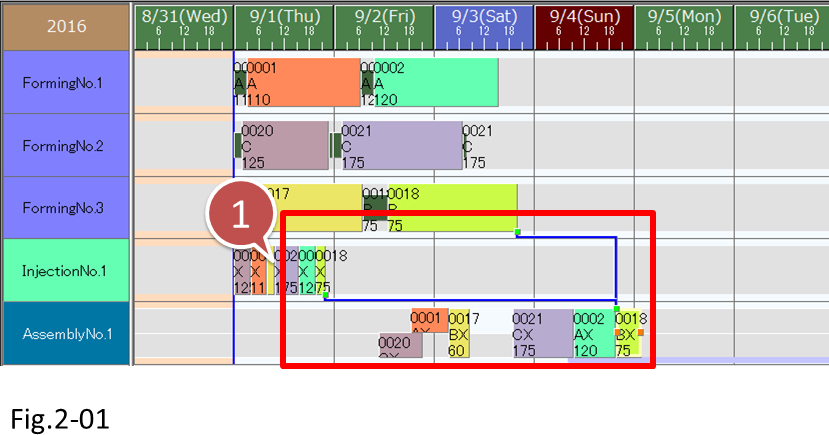

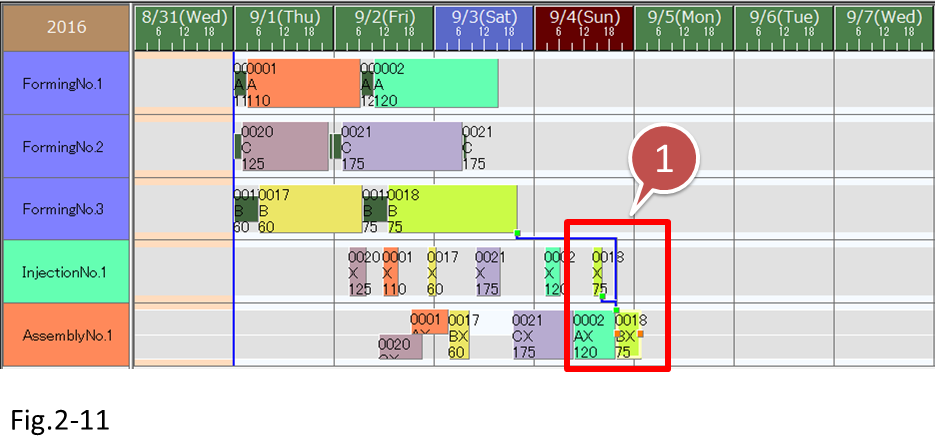

As shown in the following figure, the wait time between the Injection process and Assembly process becomes long when a reschedule is executed with a [Forward scheduling] parameter.

- The wait time between the Injection process and Assembly process becomes long.

Let's create a scheduling parameter that assigns only the Injection process backwards from the Assembly process to reduce the wait time.

■ Procedure

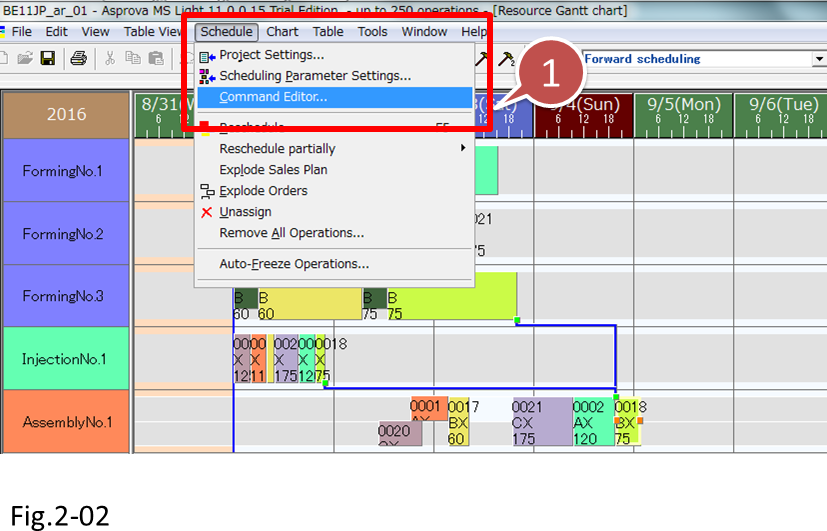

(1) Display the Command Editor dialog box.

Choose [Schedule]-[Command Editor].

- Choose [Schedule]-[Command Editor].

(2) Let's create a new scheduling parameter in the Command Editor dialog box.

Click the New button at the lower right to display the New Command dialog box. Type "Injection Backward" in the New command name box, and click the OK button.

- Click the New button.

- In the New Command dialog box that appears, type a name in the New command name box.

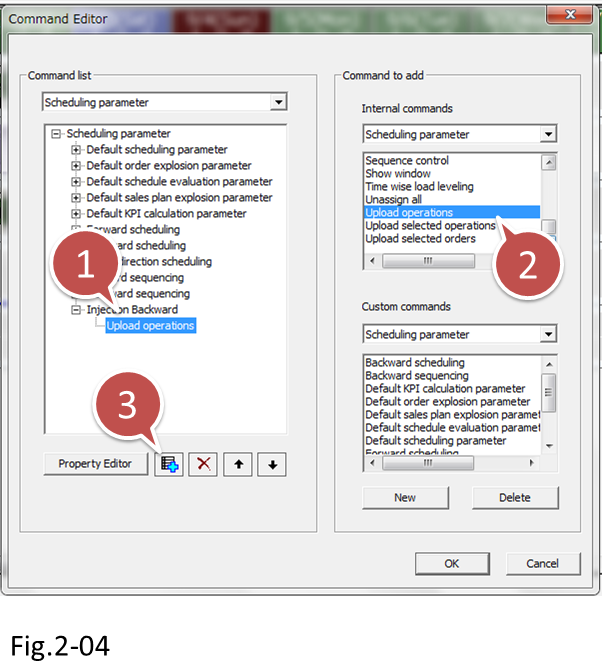

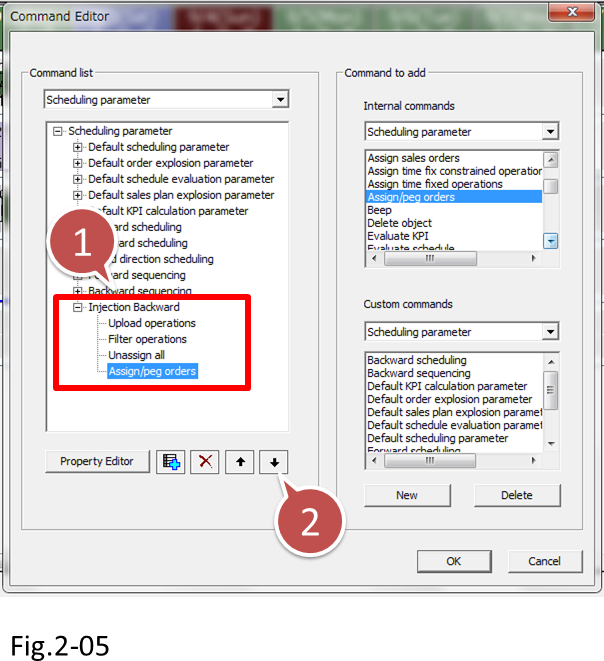

(3) Let's add the necessary commands to the [Injection Backward] scheduling parameter that has been added to the Command list.

In the Command list tree view, click [Injection Backward]. Next, from the Internal command list under Command to add, click [Upload operators]. Click the Add button to add the [Upload operators] command to the [Injection Backward] scheduling parameter.

- Click the scheduling parameter that you want to add commands to.

- Click the command you want to add.

- Click the Add button.

The [Injection Backward] scheduling parameter must execute the following commands.

• Upload operations → Upload operations command

• Filter the operations assigned to resource [Injection No.1] → Filter operations command

• Unassign the operations that have been filtered → Unassign all command

• Assign operations → Assign/peg orders command

Add three commands in addition to the Upload operations command in the [Injection Backward] scheduling parameter.

- Select the command to change the order.

- To change the order of commands, click the up and down arrow buttons.

(4) Let's set the [Injection Backward] scheduling parameter properties.

Select [Injection Backward] in the command list, and then click the Property Editor button.

- Click the scheduling parameter that you want to edit.

- Click the Property Editor button.

The Scheduling parameter Settings dialog box appears. As you learned in lesson 10, set [Assignment direction], [Assignment type], and [Assignment resource]. Here, specify backward assignment with finite capacity. Then, set [Resource selection method] to [Current resource].

- Specify backward assignment with finite capacity. Then, set [Resource selection method] to [Current resource].

For [Resource selection method], select [Optimal resource], [Priority resource], [Current resource], or [Order of appearance]. In general, for a scheduling parameter that you want to assign resources, select [Optimal resource]. For a scheduling parameter that you want to reassign operations already assigned to certain process or resources, select [Current resource].

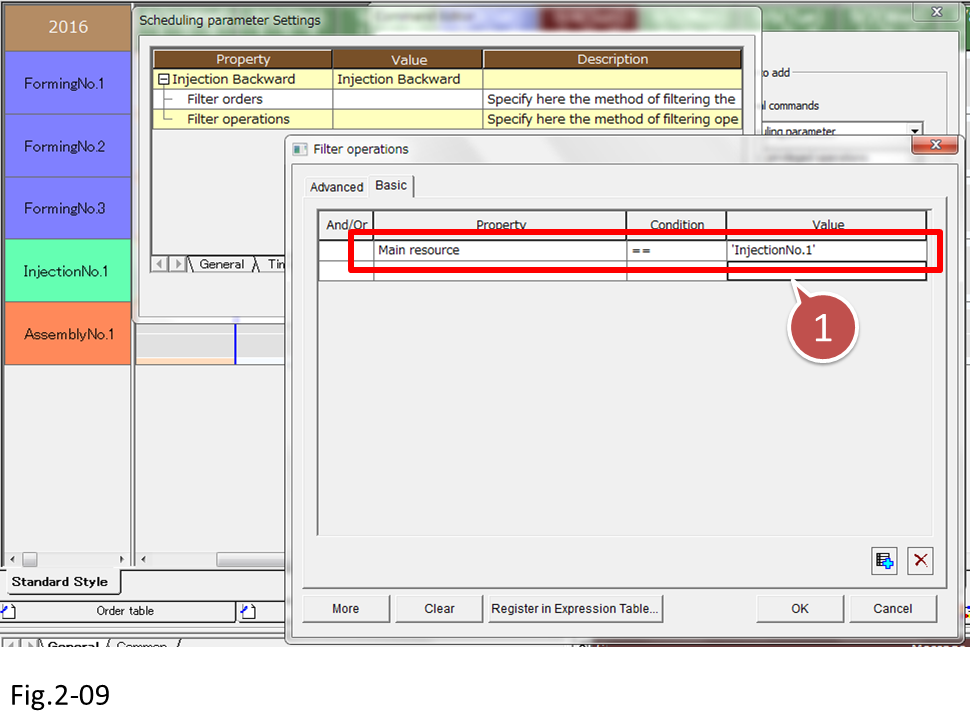

(5) Let's set conditions to filter operations that you want to assign.

Click the Filter tab. Then, click the button that appears at the right edge of the cell when you select the [Filter operations] cell.

- Click the Filter tab.

- Click the Value cell of [Filter operations], and click the button.

The Filter operations dialog box appears. Set a condition that specifies [Main resource] is equal to [Injection No.1].

- Set a condition that specifies [Main resource] is equal to [Injection No.1].

When you are done, click the OK button to close the dialog box.

(6) Switch to the [Injection Backward] scheduling parameter, reschedule, and check that the proper result is obtained.

Choose [Injection Backward] from the scheduling parameter combo box.

- Choose [Injection Backward] from the scheduling parameter combo box.

After rescheduling, we see that the operation assigned to resource [Injection No.1] has been assigned backwards, and the wait time in reference to the Assembly process has been reduced.

- The wait time in reference to the Assembly process has been reduced.

Time fence

Time fence, which was introduced in lesson 3, can be achieved by (1) filtering operations using certain conditions and reassigning (introduced in this lesson) and (2) setting the [Assignment start time] scheduling parameter.

The time span between the time set in the [Assignment start time] scheduling parameter and the scheduling basis time becomes the time fence (the protected time span)

- Set the time span of the time fence in Assignment start time.

3. Creating a Composite Scheduling Parameter

By scheduling with the [Injection Backward] scheduling parameter, we were able to reduce the wait time between the Injection process and Assembly process operations. However, we have to switch between the following two scheduling parameters to schedule:

- Forward Scheduling

- Injection Backward

This complicates the operating procedure.

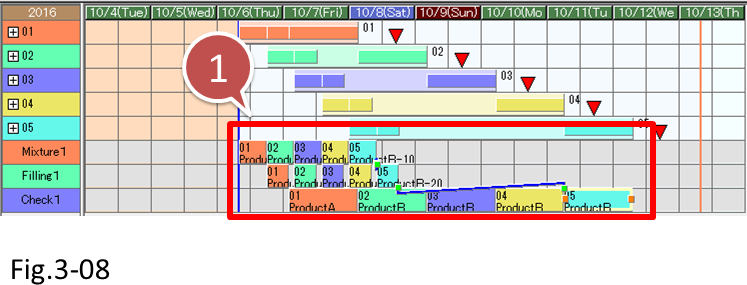

A scheduling parameter can execute multiple scheduling parameters in sequence. To do so, we combine scheduling parameters as shown in the following figure.

- A scheduling parameter can execute multiple scheduling parameters in sequence.

If you select a combined scheduling parameter and reschedule, the parameters are executed in order from the top. When the [Composite Scheduling] scheduling parameter in the above figure is executed, [Forward scheduling] is executed first and then [Injection Backward].

Let's now combine scheduling parameters so that we only have to execute once to schedule.

■ Procedure

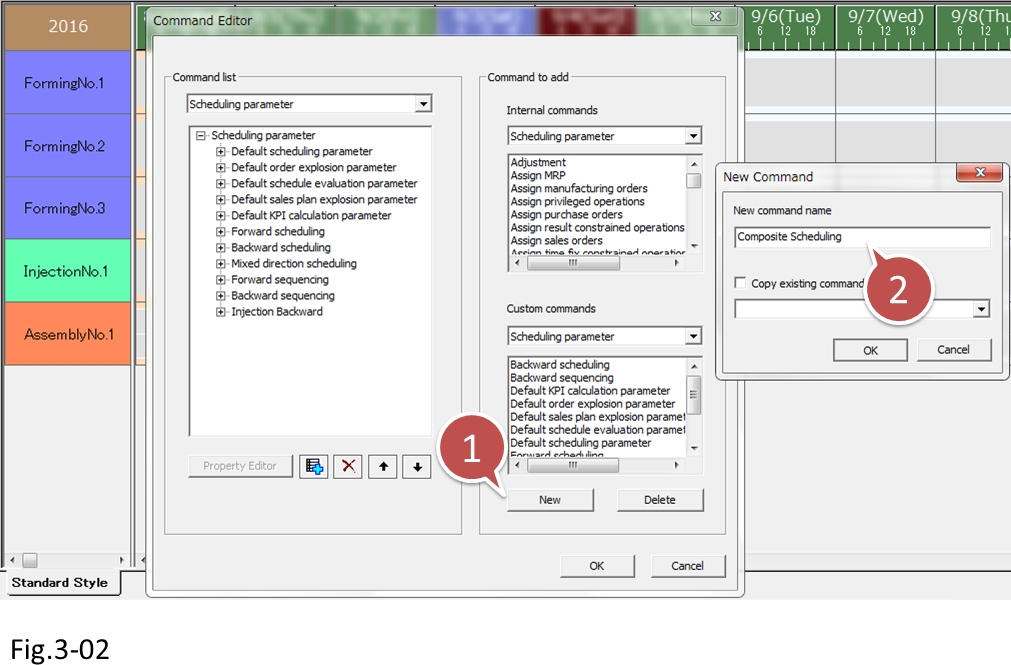

(1) Create a new scheduling parameter called [Composite Scheduling].

Choose [Schedule]-[Command Editor] to display the Command Editor dialog box. Click the New button. In the New Command dialog box, create the [Composite Scheduling] scheduling parameter.

- Click the New button

- Type "Composite Scheduling", and click the OK button.

(2) Configure the [Composite Scheduling] scheduling parameter.

In the command list, click [Composite Scheduling]. Then click [Forward scheduling] in the Custom Command list. Click the Add button to add [Forward scheduling] under [Composite Scheduling]. Likewise, add [Injection Backward] under [Composite Scheduling].

- Click [Composite Scheduling].

- Click the scheduling parameter that you want to add.

- Click the Add button.

Click the OK button to close the dialog box.

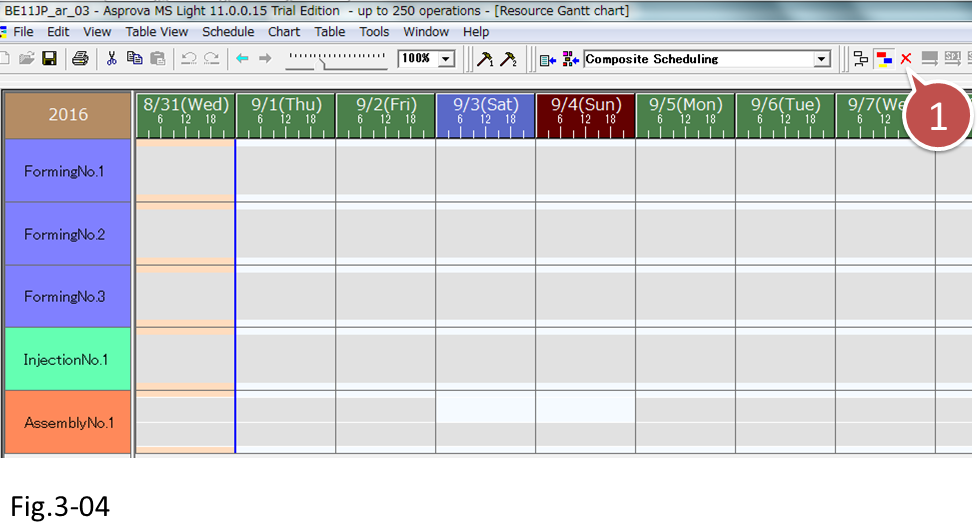

(3) Reschedule using [Composite Scheduling].

Choose [Composite Scheduling] from the combo box. Click the [Unassign all] button to unassign all operations.

- Click the Unassign all button.

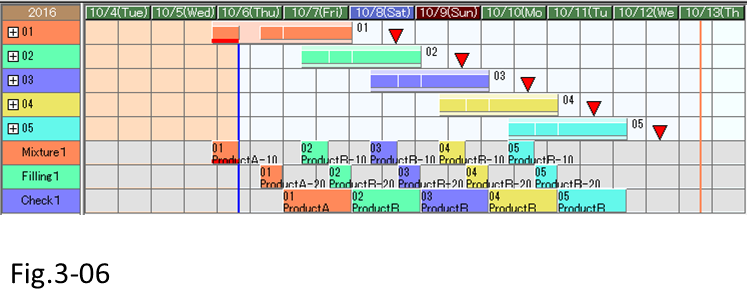

(4) When a reschedule is executed, all jobs are assigned using forward scheduling except for operations of resource [Injection No.1], which are assigned backwards from the Assembly process.

Tricks when using backward assignment

1. If operations are assigned so that they finish exactly on their due dates, any delay would cause the due dates to be missed. So it is a good idea to provide some leeway.

For example, assign operations backwards in reference to 12 hours before the due date.

* The top order Gantt chart indicates the due date and lead time of each order.

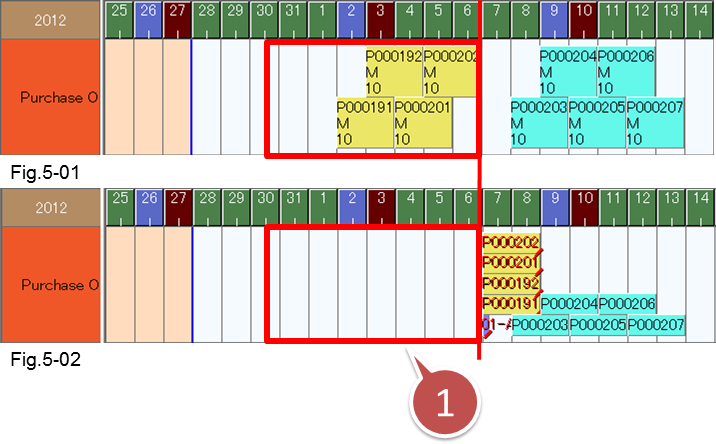

2. Squeeze operations that do not fit within a certain time span into the schedule using forward scheduling

If there is no leeway in production equipment, schedules may spill into the past.

In such a case, we can squeeze operations into the schedule by keeping as much of the dates that have been assigned through backward scheduling.

As shown in the following figure, we can avoid long wait times that would result if operations are simply assigned through forward scheduling.

Related Materials

For more details on scheduling parameters, see the following materials.