Toyota Production System

Implementing the TPS: Part One

JIT Promotion Project:

Q. When a company decides to introduce the Toyota Production System (TPS) into their company, it's very important that the management take the leading role in the project. What kind of role does the management play and how should they support the implementation of the project?

A. Before introducing various Just-In-Time (JIT) techniques, there must be a big JIT project. The top management must be aware of the risks that we are experiencing right now. For instance, because of the sub-prime loan problem the economy is quite problematic and the revenue is decreasing so top management must realize the need to decrease the outlays or costs in order to increase the profit and this risk management must be shared between people. Even though people often say that Kaizen is important they are forgetting for what purpose the kaizen must be conducted. That is cost reduction and the need for cost reduction must be shared by both the top management and the general employees. So, in order to introduce TPS we have to establish a JIT promotion project.

Q. When the company establishes this kind of project, which employees should be in the project team?

A. The president must be the chief of the project team, the vice-president must be the vice-chief of the project and also, all of the department heads must be members. In particular, the directors in charge of the manufacturing department are very important and also the production engineering department chief and the general management chief. Of these, the production management director must be the center of the project team. Actually, the president and vice-president won't be involved with the actual promotion itself. There must be some practice team for the implementation. The members of the JIT practice team must be the current routine staff that includes the people in the manufacturing department, the production engineering department, the general management department and the foreman for each process and the team leaders of each process.

5S:

Q. What exactly is the beginning practice for JIT?

A. That is the pilot line and when that has finished, its success can be moved to other processes, in order, from the final process to the proceeding process. When carrying out the pilot lines you should start from the final assembly line. However, before handling the assembly line or manufacturing line there must be 5S, which means the abandonment of all kinds of Muda. 5S represents the five Japanese words: Seiri (to clearly separate necessary things from unnecessary ones and abandon the latter), Seiton (to neatly arrange and identify things for ease of use), Seison (to always clean up), Seiketsu (to constantly maintain Seiri, Seiton and Seiso) and Shitsuke (to have workers always confirm to rules).

Q. What kinds of Muda are there?

A. Muda means unnecessary things, such as unnecessary inventory of materials, work in process (WIP) and defective products etc. It also refers to unnecessary jigs, tools and machines. Over time, various kinds of Muda can accumulate in the factory and 5S is the process of removing this Muda. Before introducing 5S most of plants and most of the processes are in a kind of mess.

Q. Obviously deciding what is muda and what is not muda is a big task. What criteria should they use?

A. Usually that criteria is one month's use in the production planning sheet and if those inventory items and/or quantities are not being used in the following month's production planning then they are considered unnecessary. The production schedule for the next month is the output of the MRP system. When they have this information then they can go around the shop floor and judge whether something is necessary or not. This is the Seiri part of 5S.

Q. What should they do with the unnecessary inventory? Should they throw it away or do they need to be careful about what they do with it?

A. At first there is a red label that must be attached to the unnecessary inventory, machines or jigs etc. Those things must be moved to the red label storage area at first and then we should evaluate whether they are truly unnecessary or not. If there are defective units amongst the inventory then this dead stock must be abolished. Even though the same unit is being utilized within the plant if they don't need that much inventory of it then that excess inventory much be moved to the red label storage for a while.

Q. Do the workers really need to understand why they are doing this?

A. At first, people often say its laborious and don't want to do it, just like children at home who don't want to clean their room. However, unnecessary inventory must be reduced. When only the necessary things are left we can then apply the Kanban card system. After the red labels are pasted and the unnecessary things are abandoned, the remaining necessary things must be rearranged. The first step was Seiri and then the next step is Seiton. This is important for 5S. Seiri is just to remove the unnecessary things and then the necessary things that were left must then be rearranged in order to use them easily. The Seiton must be carried out after Seiri has been finished.

Q. How should Seiton be performed?

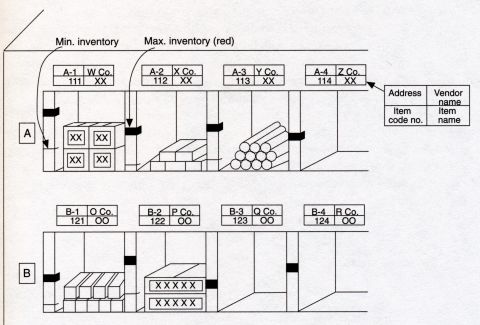

A. To carry out Seiton we make use of the indicator plate (see figure below), which has such information as the address of the shelf, the vendor name of the parts, item name and item code number. We also mark the MAX inventory and the MIN inventory levels as well. The MAX inventory is equivalent to the lot size, when we apply Kanban card system, and MIN inventory is the re-order point. When the parts are completed then they are stored here and the people working on the subsequent process will bring their Kanban card and take out the completed parts from this storage. Then, the level of the inventory will decrease to the reorder point and the lines here will start production. This indicator plate for Seiton is linked closely to the Kanban card system. This is a part of the 5S movement. For inventory reduction itself, if we reach this level then the necessary inventory does not exist in this storage and we can shorten the lead time because the inventory carrying time was reduced. When we promote the 5S then eventually we can reduce the lead-time because the inventory size is reduced. Seiton is also the prerequisite to shortening the setup time as well. When carrying out Seiton, mark the location where everything should be. For example, equipment that we use in the plant, such as a forklift truck must have the location that it is placed in determined and then marked with white lines. This is also part of the 5S movement.

Figure: The indicator plate and indication of max and min inventory quantities

Please click below for Part Two of the Implementing the TPS interview.