Q. Our company is performing plastic molding. There are 10 to 20 molding machines and we have several hundred types of mold. When making our production schedule it's essential that we decide whether a mold is usable or not. If we can't then we can't make a schedule that is executable on the factory floor. However, because there are an extremely large number of mold types we have the additional restriction that some molds made be in repair and so unavailable for use. Please tell us a way of creating a production schedule that considers molds.

Make use of production scheduling software simulations to the greatest extent

A. Bottlenecks with production schedules are not just with the main resources such as mold machines and press machines but also with the sub-resources such as molds, jigs and workers and this is what makes production scheduling difficult.

In particular, it is often the case that there is only one mold for each item so that the production schedule has the restriction that the same item mold can not be used at 2 or more places at the same time. Generally, for each item there are n mold units available or several types of mold (sub-resources) are necessary at the same time. Because of this, as the restriction conditions to the production schedule become more and more complex it becomes increasing difficult for a person to consider about all these in their head.

However, it is possible to set all the above restriction conditions in a production scheduler and simulate them.

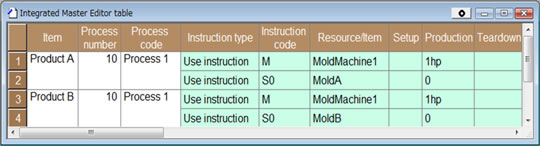

First of all、set the molding process to use a mold (Scheduler Diagram 1)、

Scheduler Diagram 1 Set up the master data for the production schedule. Specify that ProductA uses MoldMachine1 and MoldA and ProductB uses MoldMachine1 and MoldB at the same time. With this set up let's make a production schedule that considers the mold. Scheduler Diagram 1 Set up the master data for the production schedule. Specify that ProductA uses MoldMachine1 and MoldA and ProductB uses MoldMachine1 and MoldB at the same time. With this set up let's make a production schedule that considers the mold. |

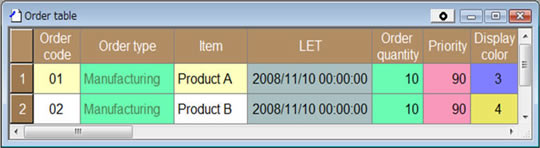

then set up the orders (Scheduler Diagram 2).

Scheduler Diagram 2 Order set up.。Set up the production orders for ProductA and ProductB. Scheduler Diagram 2 Order set up.。Set up the production orders for ProductA and ProductB. |

Next simulate with the production scheduler and the result is like Scheduler Diagram 3.

Scheduler Diagram 3 Production schedule result. MoldA is not available for scheduling on 3rd Nov due to maintenance and MoldB is not available for scheduling on 4th Nov due to maintenance. The schedule has been made specifying a calendar set with these conditions. ProductA can not be manufactured on 3rd Nov so it is scheduled for 4th Nov. ProductB can not be manufactured on 4th Nov so it is scheduled for 3rd Nov. In this way, we can make the molding machine production schedule by also considering the mold schedule as well. Scheduler Diagram 3 Production schedule result. MoldA is not available for scheduling on 3rd Nov due to maintenance and MoldB is not available for scheduling on 4th Nov due to maintenance. The schedule has been made specifying a calendar set with these conditions. ProductA can not be manufactured on 3rd Nov so it is scheduled for 4th Nov. ProductB can not be manufactured on 4th Nov so it is scheduled for 3rd Nov. In this way, we can make the molding machine production schedule by also considering the mold schedule as well. |

If we take a look at the production scheduler's results we can see that even if the molding machine is free, if the mold is not available then production can not be done. After that we if increase the data set up then we get a production schedule result close to an actual operating situation.

From here, being able to overcome the problem of trying to add new production methods just by changing the set up is one of the benefits of simulating with production schedule software.

With regard to your company's dilemma I think that the key to solving your problem is to use a production scheduler and try to actually simulate the situation with real data

Our company is performing plastic molding. There are 10 to 20 molding machines and we have several hundred types of mold. When making our production schedule it's essential that we decide whether a mold is usable or not. If we can't then we can't make a schedule that is executable on the factory floor. However, because there are an extremely large number of mold types we have the additional restriction that some molds made be in repair and so unavailable for use. Please tell us a way of creating a production schedule that considers molds.